China End Fold Woven Label Wholesale

China End Fold Woven Label Manufacturer

If you are looking for low-cost end fold woven label wholesale, contact the Chinese manufacturer LIJIE. Our factory is located in Guangdong, China, covering 3,800 square meters. We provide customized wholesale services for end fold woven labels and welcome your inquiries.

Details of End Fold Woven Label

- Material: Woven labels made of satin or polyester.

- Colors: Black, white, yellow, blue, red, pink, gold, silver, etc.

- Logo: Custom logos available, OEM logos supported.

- Minimum Order Quantity: 2,000 pieces.

- Sampling Time: 8–10 business days after artwork approval.

- Folding Methods:

- End fold

- Mitre fold

- Center fold

- Manhattan fold

- Book fold

- Shipping:

- Economical Option: By sea, approximately 1 month.

- Express Delivery: DHL, UPS, TNT, FedEx, approximately 4–5 days.

Types of End Fold Woven Labels

1. Straight Cut (No Fold)

Straight cut labels are typically sewn on all four sides, the top, or just the left and right edges. No additional folding cost is required.

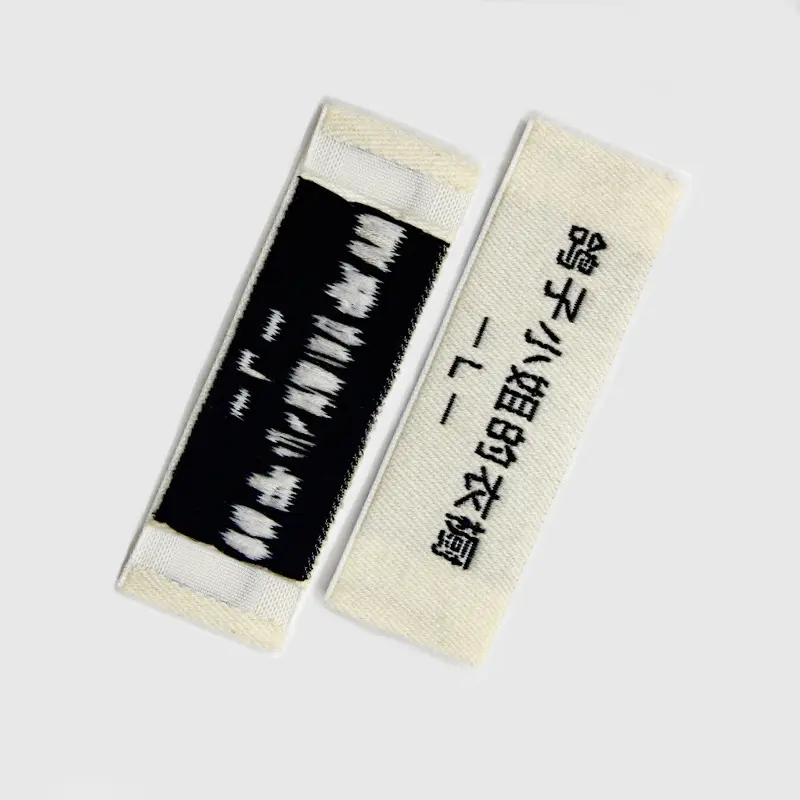

2. End Fold

Both sides fold downward. Usage is similar to straight-cut labels but with softer edges.

3. Center Fold

Folded in the middle and typically sewn into a seam. Can also be used for sleeve and hem labels.

4. Mitre Fold

Both ends fold upwards and inwards at a 45-degree angle to form a label that can be sewn into a seam. Contact our sales professionals for more details about mitre fold woven labels.

5. Manhattan Fold

Similar to center-fold labels, but the top of the label folds downward to create a flap that tucks into the bottom fold.

Advantages and Disadvantages of End Fold Woven Label Types

1. Center Fold Labels

Labels are folded in the middle to form a loop and can be applied horizontally or vertically to products.

Advantages:

- Ideal for T-shirts, pullovers, etc., often used in necklines or side seams.

- Provides space on both sides to display brand, size, and care information.

Disadvantages:

- May appear bulky on thin fabrics.

2. End Fold Labels

The sides or top and bottom are folded, suitable for sewing, heat sealing, or adhesive fixing.

Advantages:

- Soft folded edges prevent stitching from obstructing the design.

- Comfortable edges that don’t irritate the skin.

Disadvantages:

- Only the folded edges can be sewn, making it less stable in some applications.

- Limited design space, not suitable for complex information.

3. Mitre Fold Labels

Both ends fold diagonally at a 45-degree angle and are sewn into seams.

Advantages:

- Suitable for hanging, enhancing a high-end look, often used in jackets, suits, and soft garments.

- Flexible and visually appealing, ideal for luxury products.

Disadvantages:

- Requires a wider seam space and more complex production, slightly increasing costs.

4. Border Labels

Labels with raised or textured borders, no folding required.

Advantages:

- Elegant appearance, attracts attention, and offers ample space.

- Borders enhance durability, ideal for high-quality products.

Disadvantages:

- Limited design versatility, not suitable for intricate logos or instructions.

- Borders increase thickness, making it unsuitable for lightweight materials.

5. Manhattan (Book) Fold Labels

Similar to center-fold labels, but with additional folds on the top and bottom to hide raw edges.

Advantages:

- Traditional and durable, suitable for rebranding projects.

Disadvantages:

- Modern techniques offer lighter alternatives, making it not always the best choice.

- Bulky and less suited for lightweight products.

6. Custom Label Shapes

Can be designed in circular, square, or other shapes to emphasize brand identity.

Advantages:

- Unique designs that stand out, widely applicable.

Disadvantages:

- Complex production requires custom molds and special processes, slightly increasing costs.

If you are looking to purchase blank end fold woven labels, contact LIJIE. We are a China-based end fold woven label wholesaler with a 3,800-square-meter factory in Shantou, Guangdong. Our competitive pricing is one of our advantages!