Compostable Packaging Bag Manufacturing Manufacturer

Compostable Packaging Bag Manufacturing

Are you curious about how those eco-friendly and stylish compostable packages come to life? Today, we’ll take you inside our China-based LIJIE production facility, where we’ll unveil the mysteries of compostable packaging production. From raw materials to finished products, let’s explore how these "green guardians" make their way into our lives!

Raw Material Selection: Sustainability Starts at the Source

The production of compostable packaging begins with the careful selection of eco-friendly materials. Common raw materials include plant-based materials such as corn starch, sugarcane bagasse, and bamboo fibers. These materials are not only renewable but also fully biodegradable in the natural environment, truly embodying the concept of “from nature, back to nature.”

Depending on the product's requirements, the factory chooses suitable primary and auxiliary materials. For example, food packaging might require higher food-contact safety standards and strength, while industrial packaging places greater emphasis on durability and cost control.

Production Process: A Perfect Blend of Technology and Sustainability

1. Raw Material Procurement

LIJIE collaborates with professional suppliers to ensure the biodegradable materials meet environmental standards and performance requirements. All production materials undergo certifications such as TUV OK Home Compost, OK Industrial Compost, EN13432, BPI ASTM D6400, AS5810, and AS4736.

2. Customization: Tailored Products

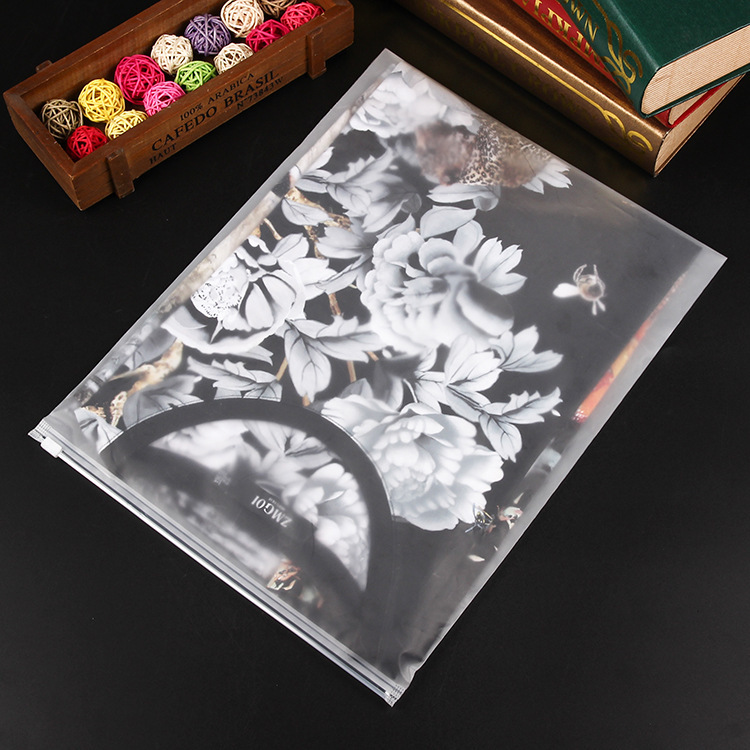

The product’s appearance and color are fully customized according to the client’s specific requests. For instance, if a client needs specific colors or functionalities for plastic bags, the factory mixes raw materials with color masterbatches in the required proportions, ensuring uniformity using high-speed mixers. This step not only determines the product’s visual appearance but also affects its physical properties and degradation characteristics, making it a crucial part of the process.

3. Blown Film and Bag Making

The blended formula is sent to the blown film machine, where it is heated and blown into thin films. During this process, temperature, pressure, and cooling speed are strictly controlled to ensure consistent thickness and uniformity of the film. After printing, the film is cut and heat-sealed by a bag-making machine to form the final compostable plastic bags.

Quality Control: Every Product is a Promise

Quality control is an integral part of the production process. The factory conducts regular sampling and testing to ensure that the physical properties of the products meet customer standards.

Environmental Significance: Let Packaging Return to Nature

The greatest advantage of compostable packaging lies in its environmental benefits. Unlike traditional plastic packaging, these products can be composted after use, allowing them to fully biodegrade in the natural environment and transform into organic fertilizer. This truly represents a "from nature to nature" circular economy model.

Future Outlook: Technological Innovation and Market Expansion

As environmental awareness increases, the demand for compostable packaging is growing rapidly. In the future, LIJIE will continue to invest in research and development to introduce more innovative products to meet the diverse needs of different industries. We also encourage more businesses and consumers to join the eco-friendly movement, contributing to the sustainable development of the planet. At the same time, policy support and increasing consumer environmental consciousness will further drive the adoption of biodegradable bags.

After this factory tour, do you have a deeper understanding of compostable packaging? From raw material selection to production processes, every step is a fusion of technology and sustainability. Let’s support green packaging and contribute to a better future for the planet!