Garment Accessories: Hangtags, Care Labels, Woven Labels

Hangtags, Care Labels, Woven Labels

Hangtags

Hangtags are primarily used in the garment industry but are also widely applied in bags, shoes, home textiles, sports goods, household appliances, and other fields. In the apparel sector, hangtags are essential for almost all types of clothing, whether it’s summer shirts, T-shirts, winter coats, down jackets, or even underwear. Different garments require different hangtags, mainly varying in material and production techniques.

The commonly used materials for hangtags include coated paper, kraft paper, black card paper, white card paper, specialty paper, and PVC. To ensure the hangtag complements the clothing or highlights the brand, various processing techniques are used. Popular techniques include UV coating, hot stamping (gold/silver), embossing, epoxy, and flocking.

Different materials + different techniques + personalized design = customized branding

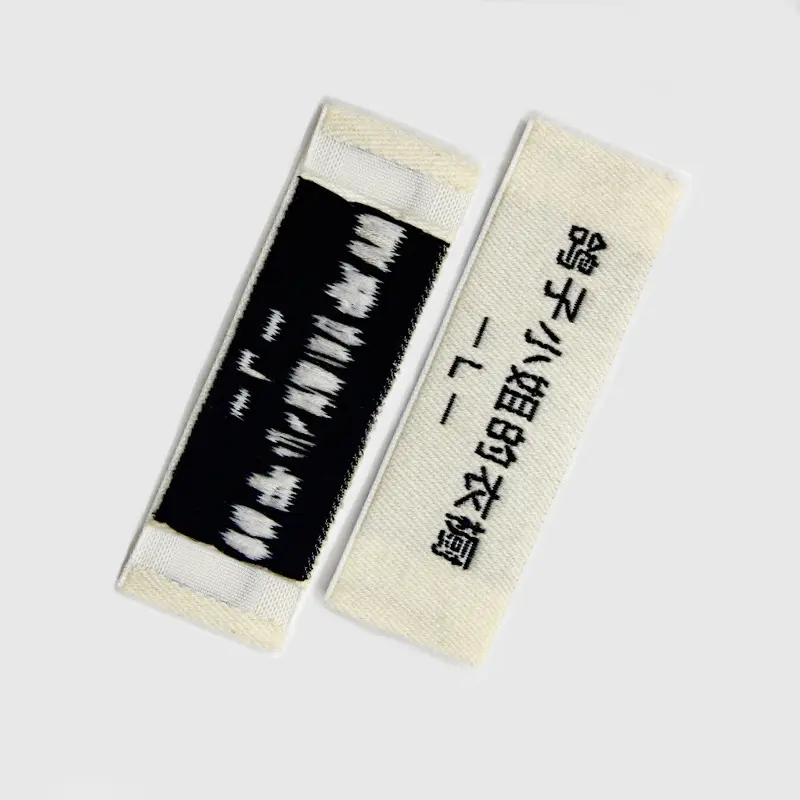

Care Labels (Wash Labels)

Care labels, also known as wash labels, washing tags, laundry labels, or care instructions, are an essential garment accessory. The English terms include care label and wash label. These labels display fabric composition and proper washing methods, such as dry cleaning, machine washing, or hand washing. They also indicate whether bleaching is allowed, drying methods, and ironing temperature requirements, helping users correctly care for their garments.

Care labels are usually sewn into the back neckline, back waist, beneath or beside the main label, or in the side seam.

Materials for Care Labels:

The most common materials include non-woven fabric and satin ribbon, though some labels use adhesive tape or flame-retardant materials, depending on specific needs.

Printing Techniques for Care Labels:

- Rotary printing – High efficiency and fast printing speed, suitable for standard requirements.

- Flexographic printing – Used for high-quality exports, particularly to Europe and the U.S.

- Silk-screen printing – Ensures durability and clear prints.

- Laser printing – The highest-quality method, producing long-lasting, premium results.

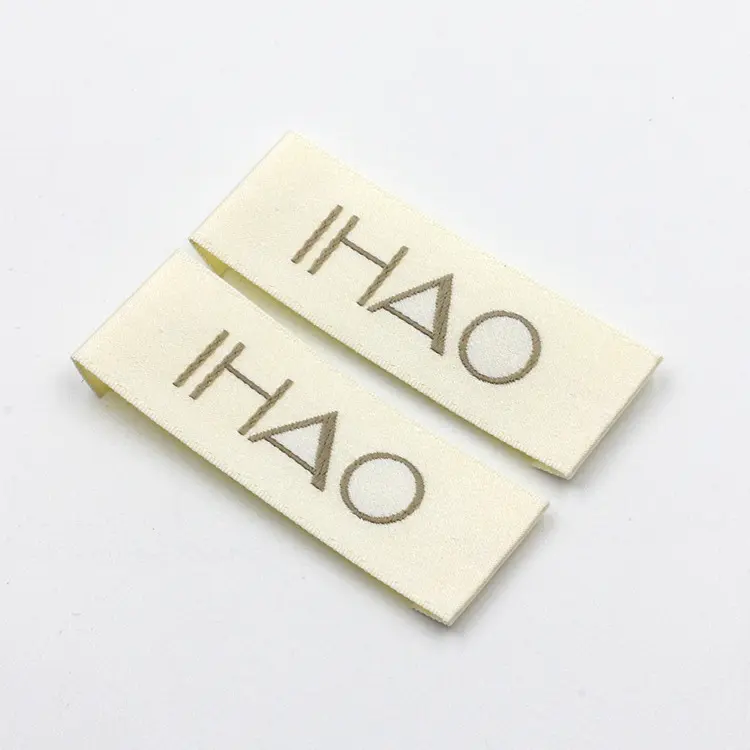

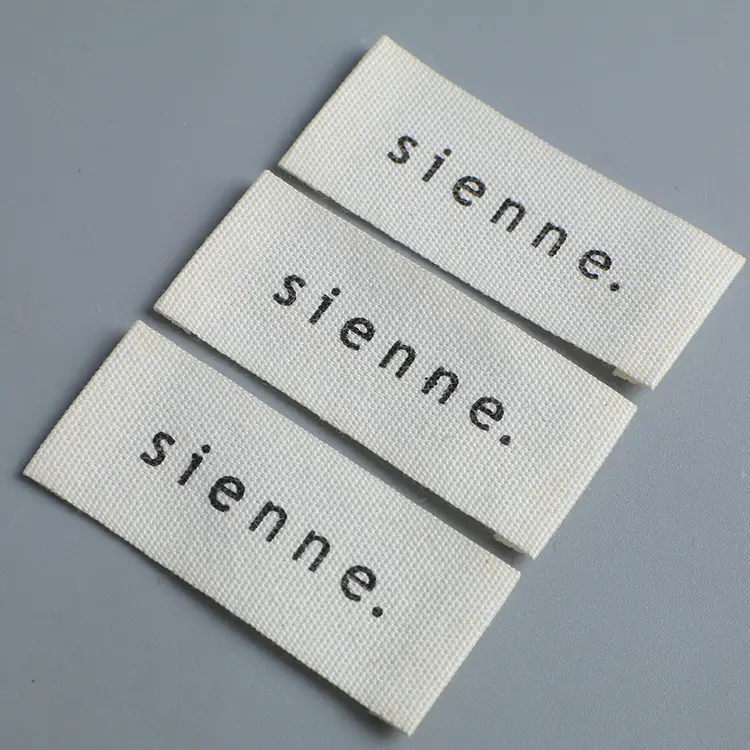

Woven Labels

(Woven labels are also known as neck labels, fabric labels, brand tags, or garment tags.)

Woven labels showcase a garment’s branding and characteristics, usually featuring a brand name or logo. These labels are created using advanced Swiss and German weaving machines and are typically made from high-quality polyester yarn. They have fine details, a textured surface, and rich colors. Well-designed woven labels not only decorate and brand the clothing but also serve as anti-counterfeiting measures (details on anti-counterfeiting methods can be provided separately).

Woven labels are ideal for premium winter clothing, suits, summer wear, women's fashion, toys, hats, and more.

Types of Woven Labels:

Computerized woven labels are categorized based on warp yarns and weaving structures. The most common warp yarn colors are black and white, combined with different weaves such as satin and plain weave. These are commonly referred to as white plain, white satin, black plain, black satin, etc. Additional classifications include double satin, jacquard, single-layer, and high-weft density labels.

Cutting Methods:

- Heat cutting – Edges are not entirely smooth, which may cause discomfort if sewn onto close-fitting garments.

- Ultrasonic cutting – Uses ultrasonic technology for smooth edges, ensuring comfort even for delicate skin. However, this method has a higher production cost.

LIJIE China offers customized services for all the above products. Our factory is located in China, with a minimum order quantity of 1,000 pieces at extremely competitive prices.