Manufacturing Process of Woven Labels

Manufacturing Process of Woven Labels

The production of woven labels mainly includes the following steps, each with its unique characteristics:

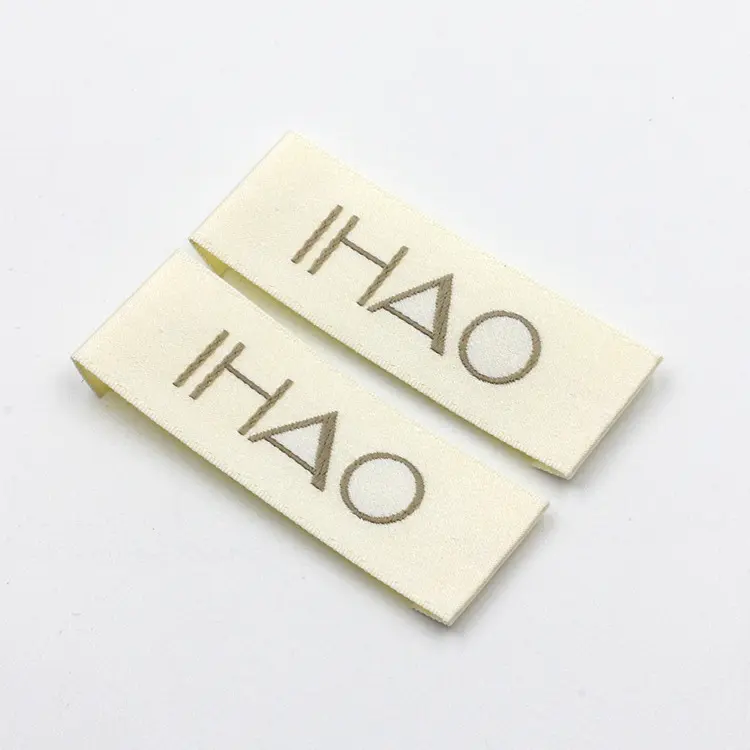

1. Woven Label Design Stage

- Pattern Design & Color Matching: Designs are created based on customer requirements.

2. Plate-Making Stage

- Plate-Making: The designed pattern is converted into a machine-readable program.

- Sampling: A sample is produced according to the program to confirm whether the colors and patterns meet the requirements.

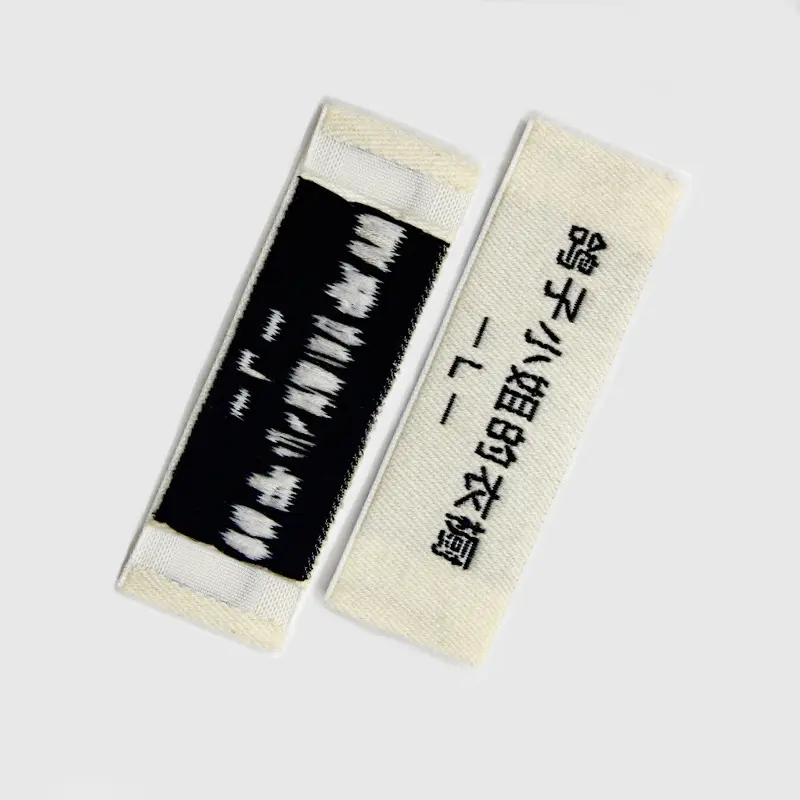

3. Weaving Stage

- Material Selection: Suitable base materials and threads are chosen according to the intended use.

- Machine Setup: The prepared program is input into the weaving machine, and the necessary materials are prepared.

- Weaving: The machine weaves the threads into the base material to form the pattern.

4. Post-Processing Stage

- Ultrasonic Cutting: The woven labels are cut into required strips after being woven by the Müller weaving machine.

- Cutting & Folding: The cut labels are further trimmed to the required size and shape.

- Edge Sealing/Slicing: Labels are either sealed at the edges or sliced according to customer requirements.

Post-Processing Features:

- Durability: Treated woven labels are more wear-resistant.

- Aesthetic Appeal: Edge-sealing and other finishing processes enhance the overall appearance.

5. Quality Inspection

- The woven labels are inspected for appearance and functionality.

6. Packaging & Shipment

- The final products are packaged and shipped to customers.

China LIJIE Factory provides customized woven label solutions for garments. Welcome to place your order!