Metal logo sticker Tags on Clothes

Metal logo sticker Tags on Clothes

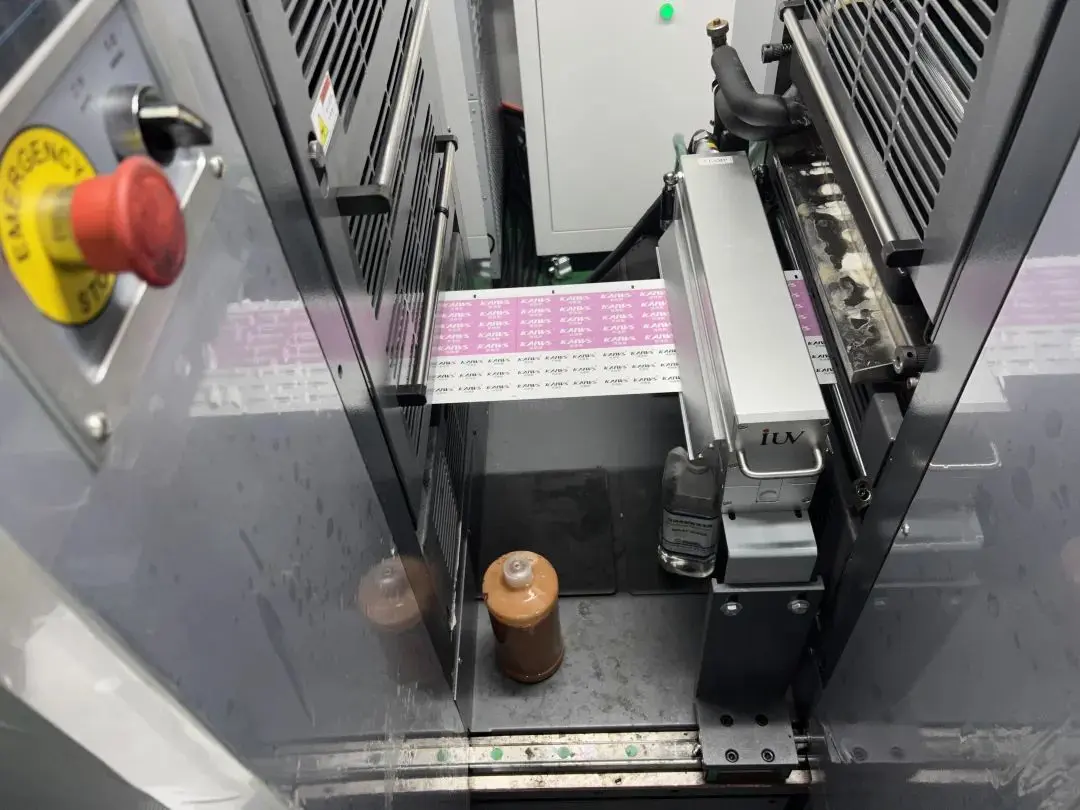

Metal tags are accessories for fashion brands, made of materials such as aluminum, brass, and stainless steel. The crafting process involves stamping, printing, or laser cutting, with optional electroplating or dripping processes. They are commonly found on clothing and leather products. A new trend is to sew them onto garments, providing high-quality finishes and durability. They are also suitable for bags and shoes. We offer customization services including shape, size, and color, at competitive prices.

Metal tags can be used for clothing, badges, medals, accessories, including embossed metal clothing tags. They can be shipped to various countries including the USA, UK, Canada, etc. As manufacturers, we aim to provide globally influential services and also offer custom bottle neck tags for bottles, gifts, and promotional items.

1. What is the minimum order quantity and price for metal tags?

- The minimum order quantity is 1000 pieces. The price is $120; prices vary based on material, size, color, and quantity.

2. What are the production and shipping times for bulk orders?

- Production time is 10-15 working days, with express shipping taking 3-5 days.

3. What materials are available?

- Available materials include zinc alloy, stainless steel, brass, aluminum, and poly materials.

4. What logo styles are available?

- Logo styles include engraving, embossing, printing, raised, cutting, and epoxy in various colors.

5. What file format is needed for production?

- Please provide vector logo files such as PDF, AI, ESP, CDR, or PSD.

6. Can samples be provided? Can samples be made first?

- Yes, samples can be provided, and you only need to pay the sample fee.

7. Can they be used on swimwear?

- Yes, metal tags are waterproof and do not fade.

8. Can we get free samples?

- Yes, we can provide free samples, and you only need to pay the shipping fee.

9. What waterproof, rust-resistant, and attractive metal tag options do you recommend?

- We recommend tags made of zinc alloy, durable, washable, and non-fading.

10. Which metal tags are waterproof and resistant to discoloration for clothing customization?

- It is suggested to use zinc alloy material for clothing customization, which is waterproof and resistant to discoloration.

11. What is the process for processing metal tags?

- Firstly, discuss basic information, then provide pricing and invoices. Secondly, make payment and confirm the design. Lastly, arrange production, with a production time of approximately 15 to 20 days.

12. Metal tags: Stainless steel or aluminum? What do you recommend?

We don't want them to be too heavy.

- We recommend using zinc alloy material, which is lightweight and does not fade easily.

13. We are looking for metal accessories, can you produce according to our requirements?

- Yes, we can produce metal accessories according to your requirements.

14. How do metal tags withstand cleaning?

- Metal tags are washable and rust-resistant.

15. What coatings can metal tags provide, are there options?

Can you provide product test reports to ensure they won't rust or oxidize on fabrics and withstand weather conditions?

- Multiple color coatings are available, although there are no test reports, the service life proves that they do not rust or oxidize.

16. What kind of metal do you typically use for metal tags?

If we choose gold color, what type of coloring is used? Galvanization or something else?

- Zinc alloy is typically used for tags, with gold coloring achieved through gold electroplating, which is long-lasting, washable, and rust-resistant.

17. How do you ship goods to Moscow, Russia - by train or air?

- Small quantities are usually shipped by courier, while large quantities may be shipped by train or truck.

17. Custom metal clothing tags, are these suitable for clothing?

Is there a price difference between different types of metal?

- Metal tags are suitable for clothing, with different metal types having varying prices, with zinc alloy being common.

19. What is the ordering process for custom metal tags?

1. Send the artwork in CDR, ESP, AI, or PDF format;

2. Provide requirements such as size, color, material, and quantity;

3. Make payment upon receiving the price and invoice;

4. Confirm the design;

5. Arrange production and shipping.