What is Screen Printing?

What is screen printing?

Screen printing is to make a mesh through screen printing to leak ink onto the substrate. Compared with the three major printing methods of convex, flat and concave printing, it has a wider range of printing and has more advantages. There are also more and more types of inks and printing materials used.

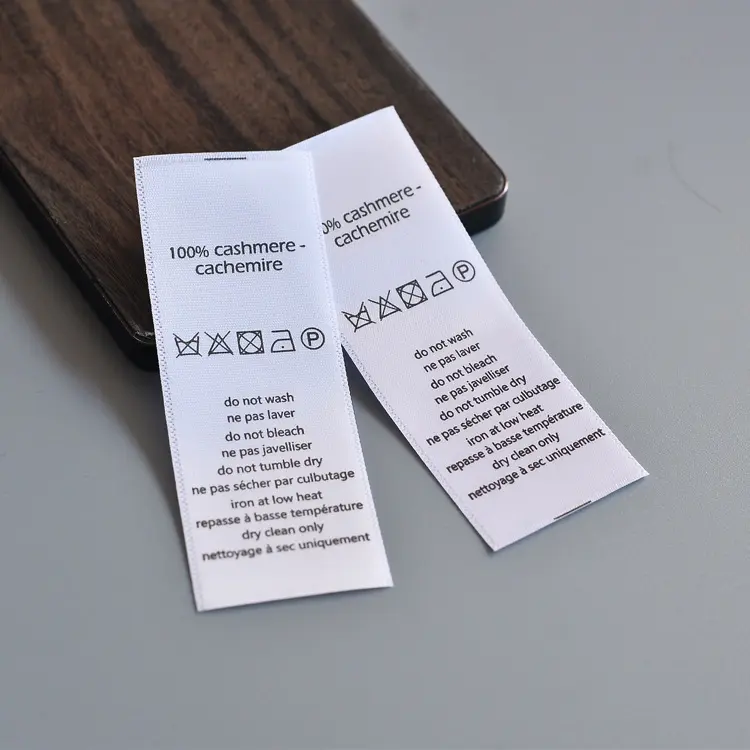

Screen printing is not limited by the size and shape of the substrate. It can be printed on molded objects of different shapes and concave and convex surfaces. --The layout is soft and elastic, and it is a kind of printing with the smallest printing pressure.

The silk screen printing method has thick ink and strong adhesion. The printing thickness can reach 30-100μm, the ink has particularly strong hiding power, and the printed images and texts have a strong three-dimensional effect, which is unmatched by other printing methods (the thickness of the ink layer can also be controlled).

Suitable for various types of inks: It has strong adaptability and can be used for printing with any kind of coating, such as oil-based, water-based, synthetic resin, powder and other inks. Inks and coatings can be used as long as they can pass through the mesh of the screen. It can print in single color, and can also print in color by registering and screening.

It has strong light resistance: it can put light-fast pigments and fluorescent pigments into the ink in a simple way, so that the printed images and texts can permanently maintain their luster and are not affected by temperature and sunlight, and can even glow at night.

Plate making is convenient, cheap, printing methods are flexible and diverse, and the technology is easy to master.

Screen printing is widely used in film panels in the electronics industry

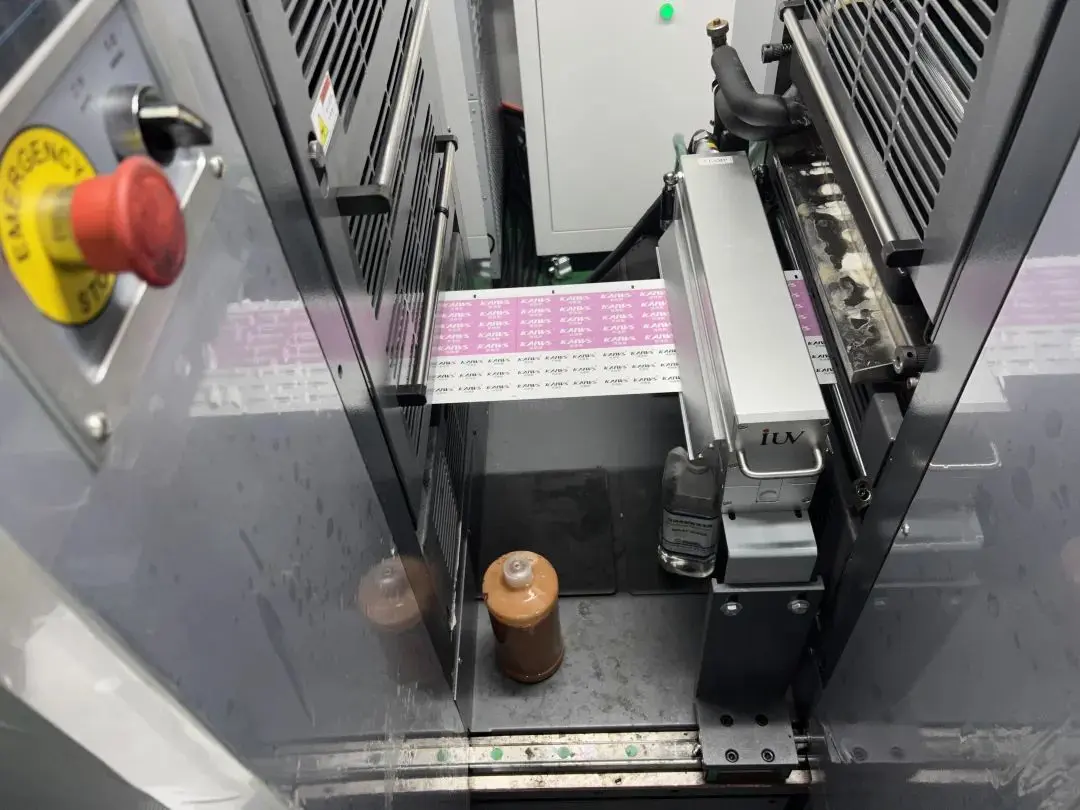

Screen printing process: original → original → screen version → printing → development → drying → printing → drying → finished product inspection → printed matter