What Are the Materials Used for Plastic Packaging Bags?

What Are the Materials Used for Plastic Packaging Bags

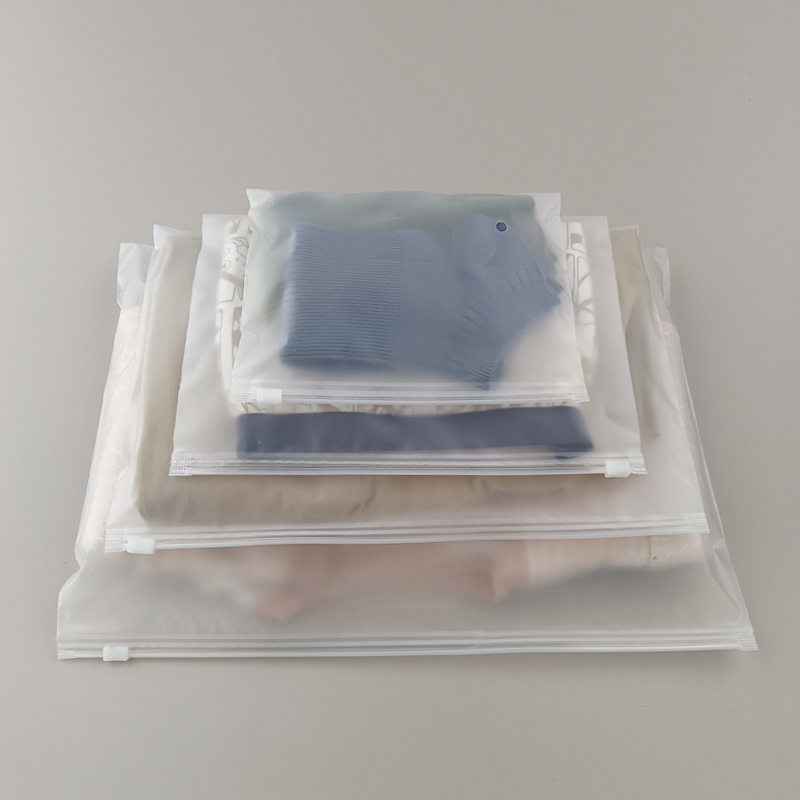

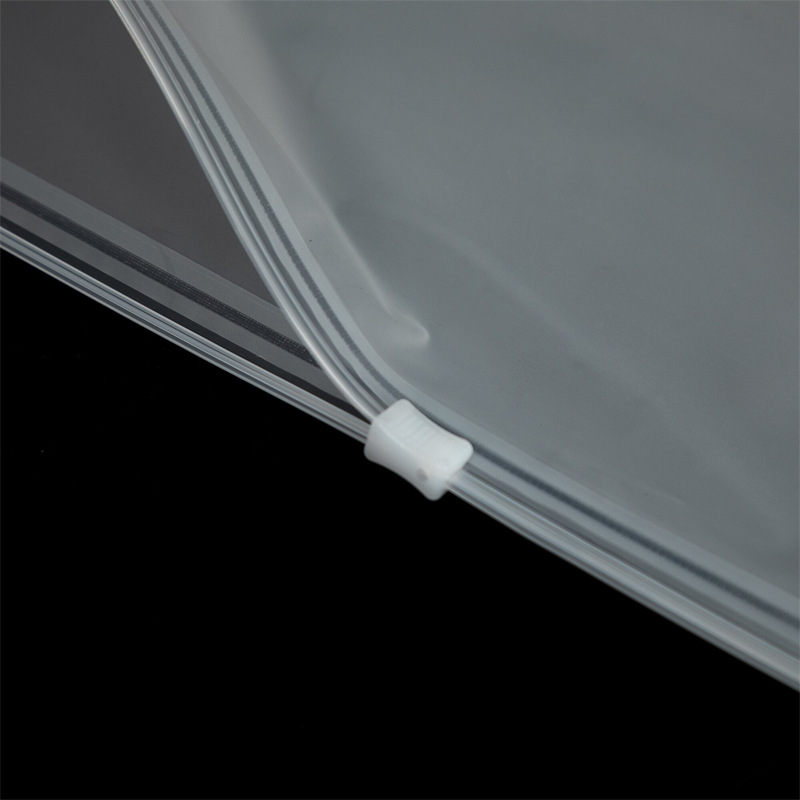

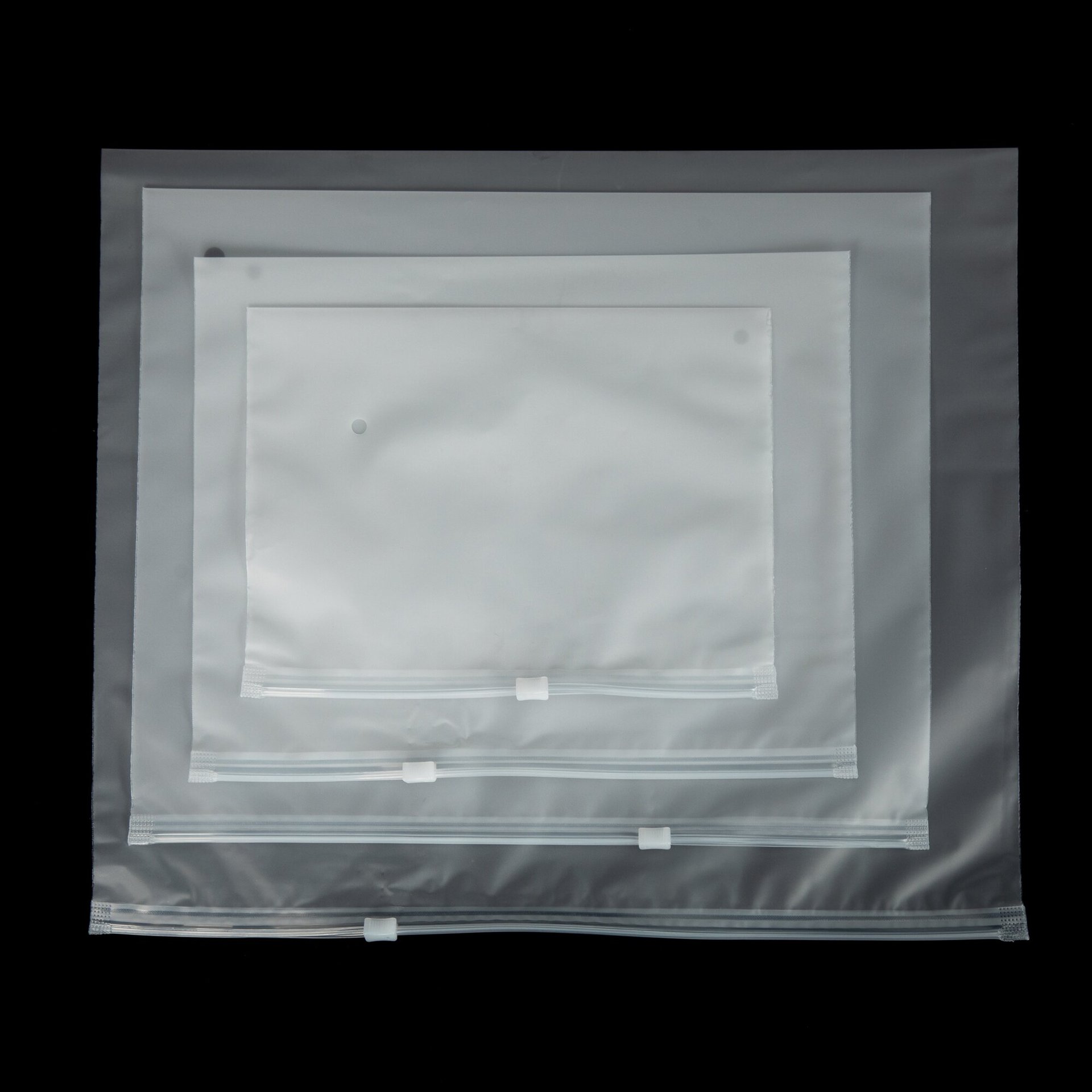

There are many types of plastic packaging bags, such as self-sealing bags, tote bags, T-shirt bags, and flat bags. Although they are collectively referred to as plastic packaging bags, their materials and quality vary. Below is a detailed explanation of the different materials used.

1. Low-Density Polyethylene (LDPE)

This material offers good tensile strength and hardness, with a bright appearance. It is mainly used for making supermarket T-shirt bags.

2. High-Density Polyethylene (HDPE)

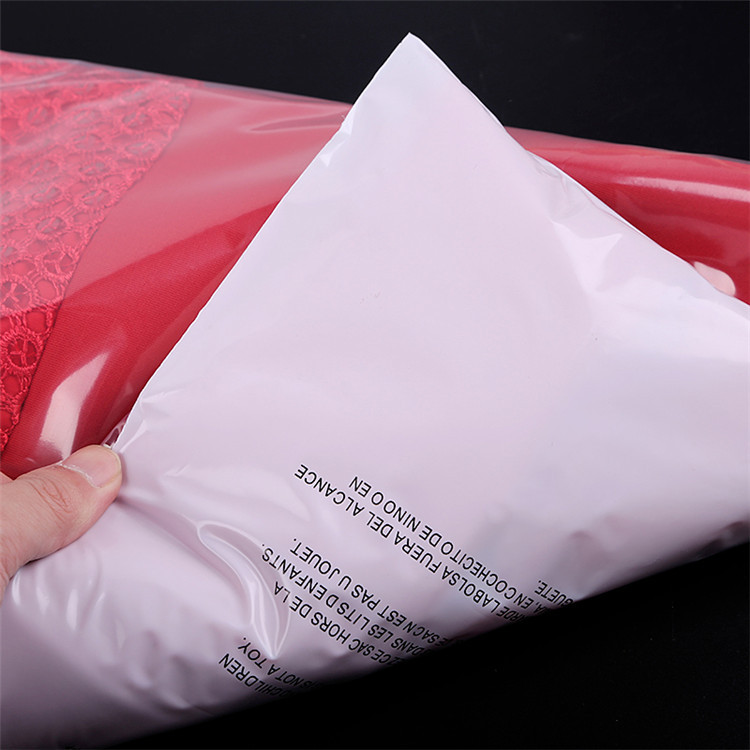

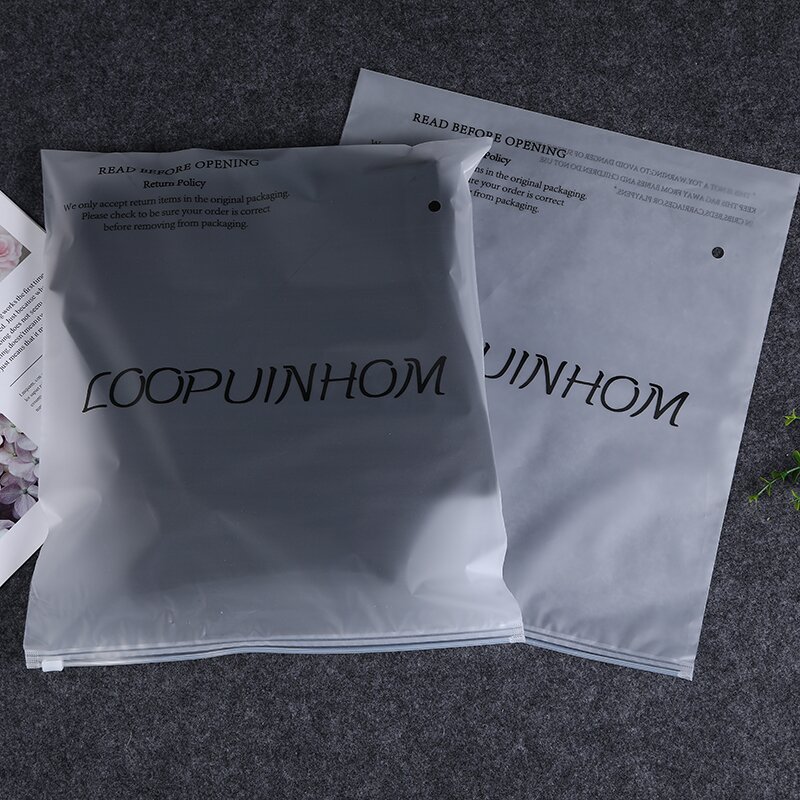

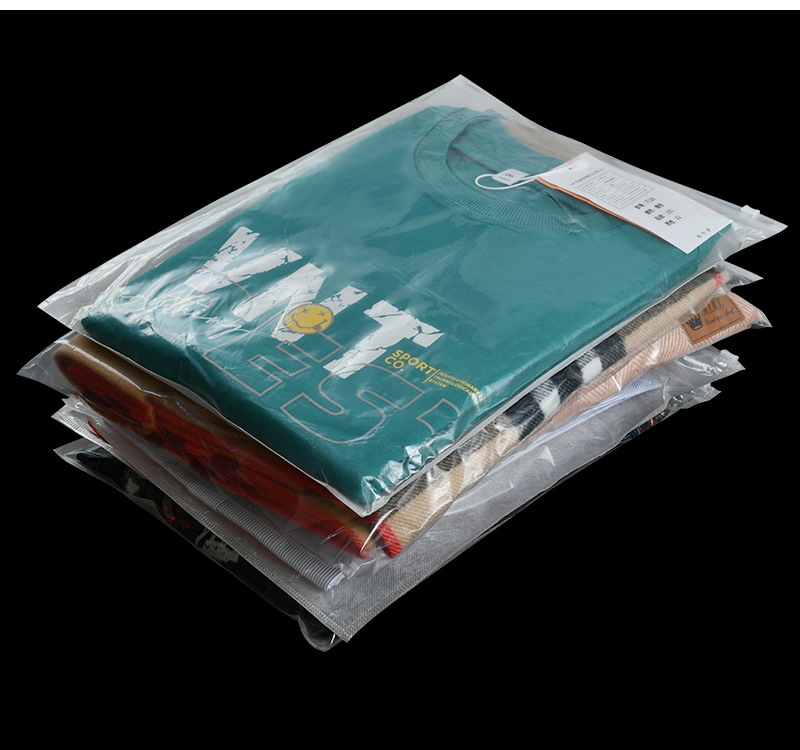

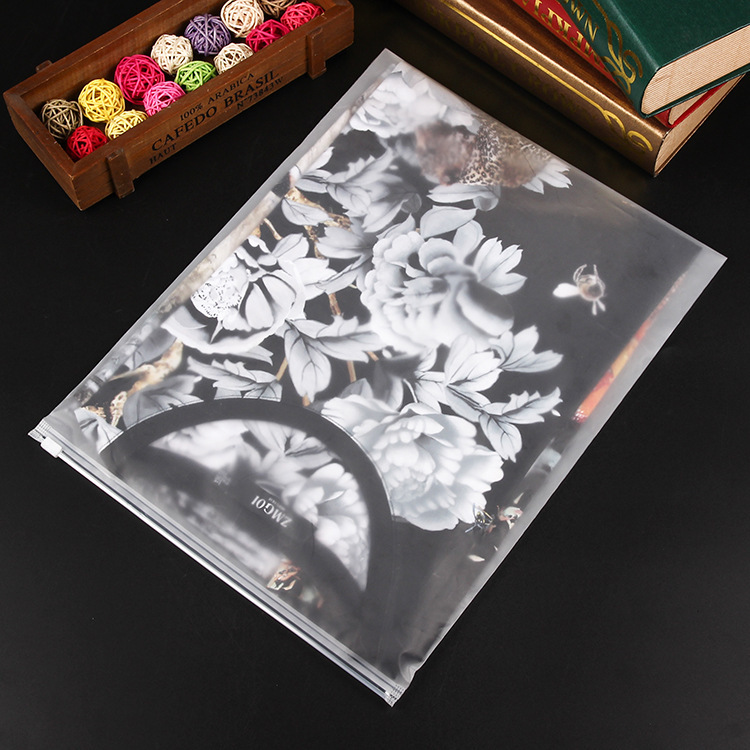

HDPE is softer, has a smoother surface, and is more flexible than LDPE. Its appearance is glossier, making it a popular choice for garment bags and gift bags. Custom plastic packaging bags made from HDPE are generally considered higher-end compared to those made from LDPE.

3. Polyvinyl Chloride (PVC)

PVC itself has high strength, corrosion resistance, and is non-flammable. However, to enhance heat resistance, flexibility, and elasticity, additives such as plasticizers, stabilizers, and anti-aging agents are introduced during production. These additives can be toxic, making PVC unsuitable for food packaging. Instead, it is commonly used for cosmetic packaging and box covers.

4. Polypropylene (PP)

PP has a lower density and superior strength, stiffness, hardness, and heat resistance compared to LDPE. However, it is brittle, prone to aging, and not very wear-resistant. As a result, it is mainly used for clothing and textile packaging.

China LIJIE offers wholesale plastic packaging bags with logo customization options. Large orders enjoy better pricing—welcome to place your order!