Custom Printed Label Production Process

Custom Printed Label Production

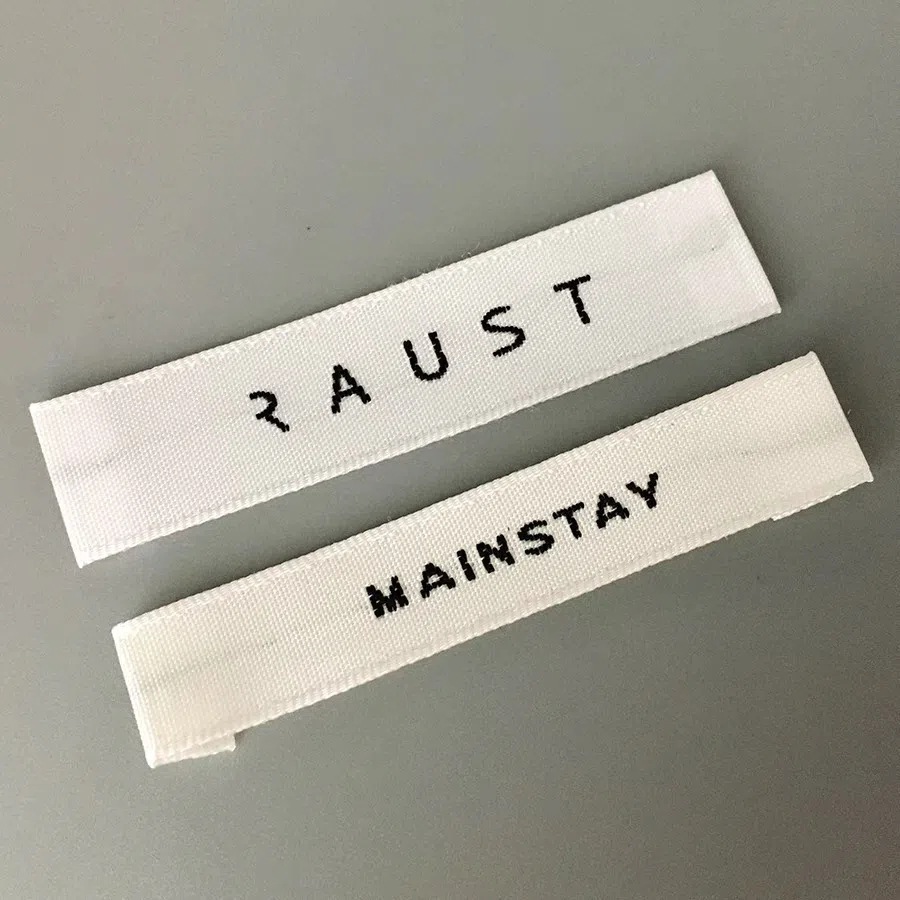

The production of custom printed labels (with logos or text) is a precise process involving multiple key steps to ensure high-quality final products. From material selection to final delivery, manufacturers must strictly adhere to each stage. This article will guide you through the complete label printing process. China LIJIE offers wholesale custom clothing labels at competitive prices—welcome to place an order!

1. Label Material Selection

The first step is choosing the right label material. Common label materials include cotton, satin, PU, and Tyvek, with the specific choice depending on product requirements. For example:

- Soft Satin: Suitable for labels that come into contact with the skin, offering a comfortable feel.

- Tyvek: Durable and tough, ideal for labels requiring high strength.

2. Printing Methods and Techniques

Labels are typically printed using advanced printers, with different printing methods suited to various materials and design needs, including:

- Flexographic Printing: Uses flexible printing plates to transfer ink onto materials. It is fast and suitable for large-scale printing.

- Thermal Transfer Printing: Transfers ink onto labels using heat, offering excellent durability—ideal for care or laundry labels.

- Digital Printing: Uses CMYK color printing for high-resolution images, perfect for small batches and personalized labels.

- Offset Printing: Transfers ink through printing plates and rubber blankets, ensuring stable quality for mass production.

3. Label Cutting

After printing, labels must be cut to the specified size and shape. Manufacturers use specialized label cutting machines to ensure clean and aesthetically pleasing edges.

4. Quality Control

To guarantee that all labels meet high standards, manufacturers conduct strict inspections on printed and cut labels, removing defective or incomplete products to ensure that customers receive only high-quality finished labels.

5. Packaging and Shipping

After quality inspection, the finished labels are securely packaged to prevent damage during transportation. Fast and reliable logistics ensure that orders are delivered on time. Additionally, customers can opt for an "Express Order" service to accelerate production and shipping, shortening the standard process by 2-3 working days.

By following these steps, manufacturers can provide high-quality custom printed labels to meet customers' unique needs.