Why Are Clothing Labels Designed on the Collar?

Why Are Clothing Labels Designed on the Collar

Many people have experienced discomfort caused by clothing labels at the back of the collar. Even if the clothing itself is comfortable, the presence of the label can cause skin irritation and reduce the overall wearing experience. So why do manufacturers place labels in such an inconvenient location? The answer lies in branding and marketing strategies.

Imagine if the logo were placed on the lower inside of the garment—very few people would see it. Manufacturers do not want to waste this valuable opportunity for secondary brand exposure. That’s why it is common to see brand logos placed prominently on various parts of clothing. In cases where an external logo is not suitable, manufacturers may choose to weave the brand name directly onto the inner lining. However, if neither an external nor an inner lining label is feasible, the simplest and most cost-effective option is to attach a label to the back of the collar. Compared to woven inner linings, woven labels are a more economical choice.

To reduce discomfort, manufacturers have developed solutions. Some improve the material used for the labels, while others design them to be removable. If you examine a collar label closely, you will notice that it is often stitched with large, easy-to-remove stitches.

In general, people only pay attention to collar labels when they cause discomfort. But what exactly causes this irritation? The answer lies in the manufacturing process.

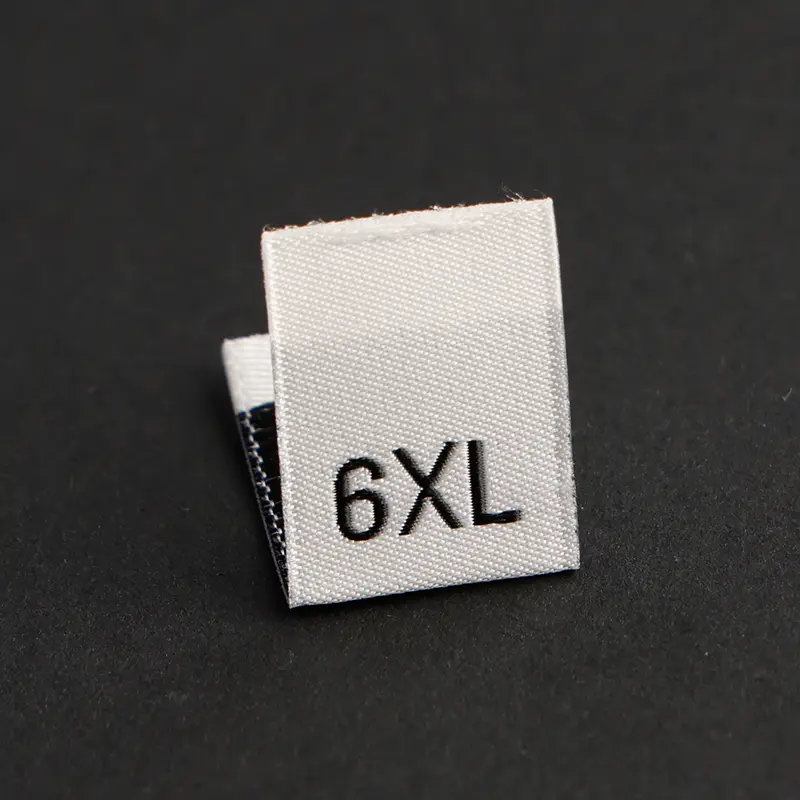

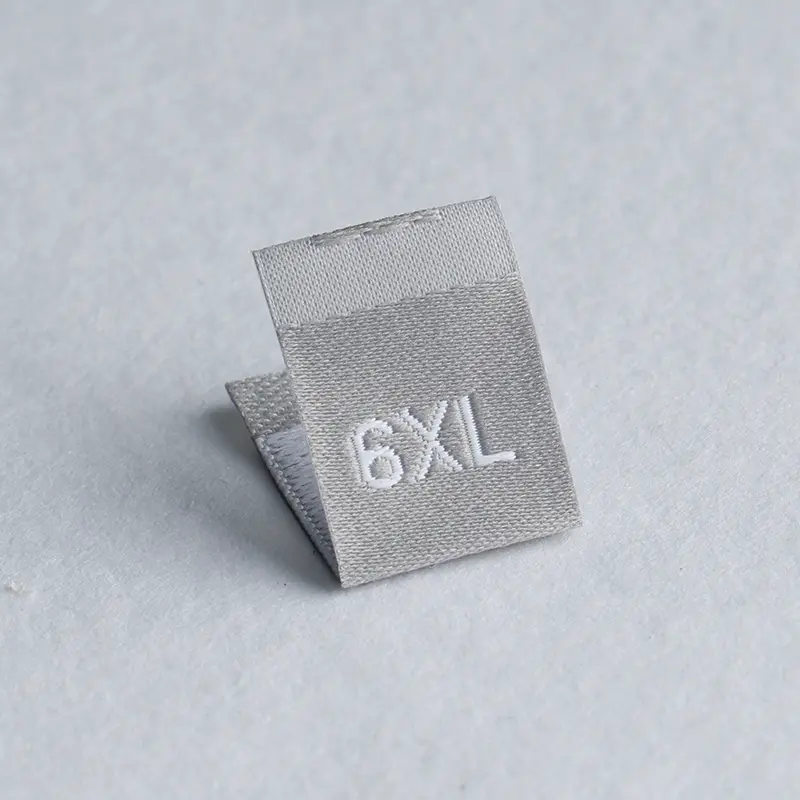

There are two main types of label production: woven labels and printed labels.

These labels are made using ink printing and include care labels, size tags, hang tags, and certification labels. Many clothing manufacturers prefer printed labels because they are more efficient to produce and more cost-effective than woven labels.

2. Woven Labels

Woven labels are made with weaving machines, offering high precision and clarity, even for small fonts. They can feature multiple colors, but their edges can feel rough due to the heat-cutting process, which can cause irritation to the skin. However, modern advancements have introduced ultrasonic cutting, which produces softer edges, though at a higher cost than heat-cut labels.

There are also different weaving techniques for woven labels:

- Satin Woven Labels

These labels are made using shuttle looms and have soft edges without the need for additional cutting. They are smooth, glossy, and feel gentle on the skin. However, they have low production efficiency, take longer to produce, and have limited color options (white, beige, black, etc.). They are typically used in high-end fashion and suits.

- High-End Edged Woven Labels

These labels have a thick, high-quality texture with seamless, integrated edges (similar to how sweater cuffs are finished). This prevents deformation over time, making them a popular choice for premium brands.

Since different production techniques involve varying costs and materials, the wearing experience can also vary. Each method has its own advantages and cannot be completely replaced by another. If a collar label feels uncomfortable, the simplest and most effective solution is to remove it.

China LIJIE provides wholesale clothing labels and supports customization. Welcome to inquire and purchase.